Effects of Refractive Index on Lens Action

Mitsui Chemicals India Blog Series

2022.04.18

Mitsui Chemicals India Pvt. Ltd.

Eyeglasses are much more than just a means of correcting vision. Selecting proper lens material is crucial to determining the precision of eyeglasses. Lens quality depends mainly on the refractive index magnitude of the lens material. According to a recent report, nearly 75% of the adult population worldwide requires vision care products. Eyeglasses also act as a protective shield for our eyes against the Sun's harmful UV radiation. Professionals, who have extensive working hours on computers, smartphones, etc., require eyeglasses to prevent their eyes from the screen's blue light radiation. Besides, eyeglasses have also become a way to mark a fashion statement.

Eyeglasses do not just enhance our vision; they have become a part of our lifestyle. They are supposed to be comfortable and effective too. But choosing the right style of eyeglasses isn't enough; we also need to understand the significance of proper lenses. This article focuses on the fundamental characteristics of lens material that can significantly alter your vision.

The Need to Choose Proper Vision Care Product

The primary step of buying a pair of eyeglasses is selecting the most appropriate lenses for them. With several alternatives in the market, finding a product that meets all your requirements becomes mandatory. Prescription lenses function by bending light and focusing directly on the focal point of the retina. The position of the focal point determines whether a person is nearsighted (myopia) or farsighted (hyperopia). The main criteria for selecting lenses are:

1. Standard quality

2. Their attributes (such as single vision, bifocal, trifocal, etc.)

3. Their coatings (such as anti-reflective, anti-fog, anti-scratch, etc.)

Thorough product research from the consumer's perspective makes it easier to choose an appropriate product. Consumers should consider the following essential factors when selecting lens materials:

1. Choosing appropriate lens design:

The design of lenses (aspheric lens, spherical lens, etc.) can drastically alter their quality. The lens must allow you to see clearly through the whole lens and not just a particular portion of it.

2. Refractive index:

The refractive index balances the bending of light. Primarily, the prescription, size of the eyeglass frame, and its function determine the refractive index of the lens material. A higher refractive index indicates a thinner lens due to more efficient light bending.

3. Coatings:

The lenses must be coating-friendly. Otherwise, the coating on the lens may peel and crack, rendering it unsuitable for use. Lens coatings come in a variety of choices, including anti-fog, anti-reflective, scratch-resistant, etc.

4. Technical considerations:

There are different types of lenses available in the market (such as photochromic, polarized, tinted, etc.) to meet specific user requirements. For instance, photochromic lenses limit exposure to UV light and blue light, making them safer to use.

It is obligatory to have a prior understanding of the product from the consumer's perspective. High refractive index lenses outperform standard lenses for people with severe vision-correction needs (such as astigmatism, myopia, hyperopia, and so on). Because they bend light more efficiently, high refractive index lenses are thinner and lighter in weight than traditional lenses with less material. As a result, it is less noticeable to others and more comfortable to wear.

MRTM: A Worthy Solution

Ophthalmic lenses are sold under lens manufacturer brands. MRTM is a high refractive index lens material manufactured by Mitsui Chemicals India. It is recommended by opticians and has gained consumer interest on a large scale. It complies with the industry standard for high-refractive index lens materials. Mitsui Chemicals is a globally leading lens material manufacturer in the market. The following characteristics of MRTM lens material differentiate it as a distinct and superior choice for lens manufacturers:

1. High-Refractive Index:

MRTM is available in three different refractive indexes (1.60, 1.67, and 1.74), enabling us to make more thin and lightweight lenses for eyeglasses.

2. Strength:

The material meets the criteria of the US FDA's Drop Ball Test, which ensures its damage-proof rigidity against a falling object. It also satisfies the Butterfly test, which Japanese lens manufacturers perform to ensure its strength for rimless frames and maximum bending capacity.

3. Durability:

It is highly thermal and weather-resistant, resulting in product longevity and compatibility. It effectively works with coating materials and films, making the coating more durable and highly resistant to cracking and peeling under all conditions.

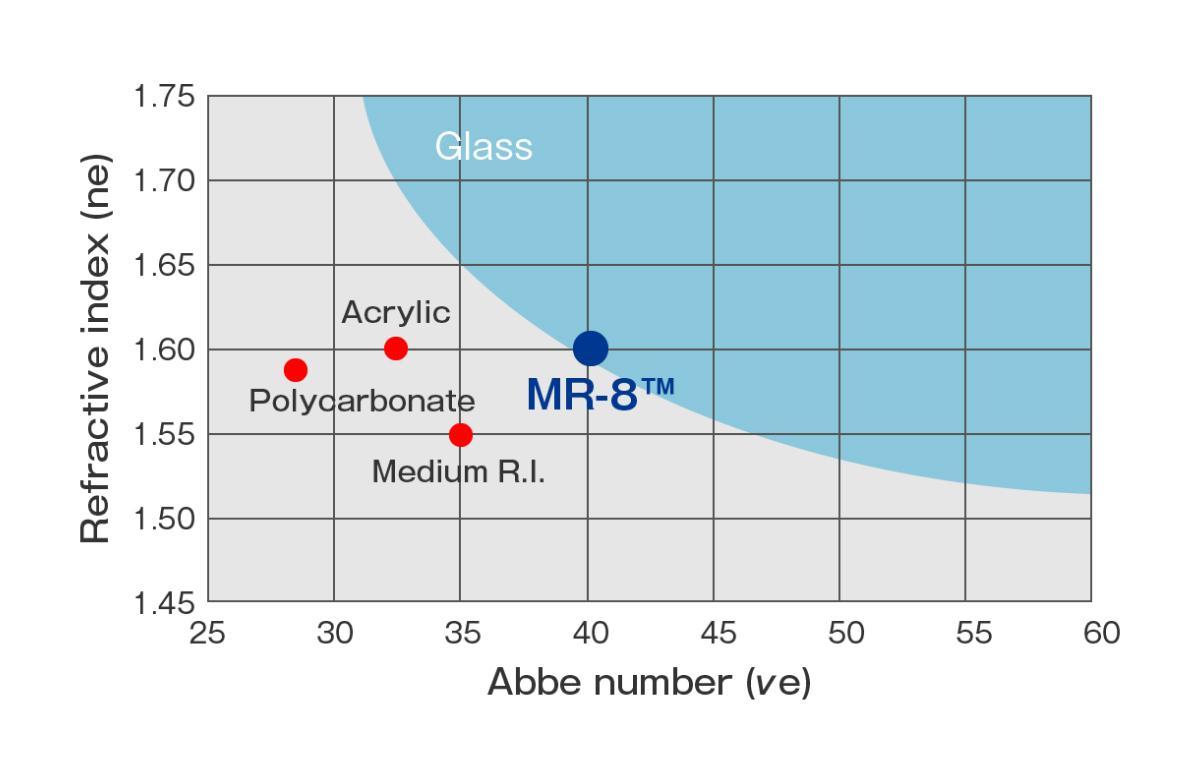

4. High Abbe Number:

Usually, high refractive index lenses have low Abbe numbers, which results in chromatic aberration of light. It refers to the lens' inability to focus all image colors on the focal point. But MRTM lens material has a high Abbe number and high refractive index. It counters these issues and helps produce a more precise version of the image and lower the chromatic aberration of light.

MRTM: Enhancing Your Lifestyle

MRTM is made of this urethane resin through polymerization technology. It enables the making of thin and strong eyeglass lenses, making them impact-resistant and break-proof. It also allows us to manufacture photochromic and polarized lenses that are both fashionable and functional. As a result, it also has user-friendly properties that make it more feasible and convenient, which are as follows:

1. Clear vision:

Compared to ordinary lens materials, it provides minimal discoloration and clearer vision even after prolonged use.

2. Fashion-oriented lenses:

Eyeglasses play a vital role in exhibiting your personality. Hence, it is suitable for application in your desired eyeglass shape and design due to its strength and workability.

3. Available in color variation:

Sunglasses become a necessity when we are outdoors, especially in bright sunlight. It shields your eyes from UV rays, dirt, and other contaminants, as well as improves your overall appearance. Because of its high tint, our lens material is suitable for sunglasses with a wide range of color variations.

4. Comfortable:

It is of utmost importance that the user feels comfortable while wearing their glasses. Thus, we have developed this innovative material which has a slim and lightweight appearance. It liberates you from the burden of broad and heavy glasses that strain your eyes and constraints your ability to work.

A Better Version with a Clear Vision

We are at the dawn of the digital age in a rapidly growing world. The majority of people rely heavily on computers, smartphones, and other digital platforms to perform their tasks. It yields better results but also negatively impacts our vision. Given the current scenario, it is time for society to become attentive to healthcare, especially vision care. Regardless of age or circumstance, protecting one's eyes should become our top priority.

At Mitsui Chemicals India, our solutions aim to enhance the quality of life and the environmental impact through our Rose Value™ and Blue Value™ benchmarks, respectively. Our UV+420cut™ technology is another such solution that can be utilized in making vision care equipment (including both corrective and non-corrective range of eyeglasses). We design and manufacture our products and solutions intending to improve the consumers' lifestyles.

Contact us to inculcate our vision care products and solutions for your business and lifestyle.