Prioritizing Sustainability: What Can Recyclable Materials Offer?

Mitsui Chemicals India Blog Series

2022.09.08

Mitsui Chemicals India Pvt. Ltd.

Plastic has shelved our lives at ease with advanced accessibility & applicability until we realize the devastation it causes. Given that it is readily available in different forms- plastic bags, straws, ice cream sticks & other packaging materials; enforcing the ban is a real challenge. When considering the scale of the plastic industry, the ecological impact is projected to escalate for the worse.

Over the past few years, the government has recognized the need to innovate 100% recyclable and reusable materials. In the lieu of this, India’s Ministry of Environment has phased out the utilization of single-use plastic, effective from July 1, 2022. Therefore, to reiterate the mission of a circular economy, people should outcast plastic and source compostable substrates.

This article addresses the devastating impacts of plastic and denotes the switch to recyclables concerning plastic waste management.

What Are Single-Use Plastics?

In the primitive sense, single-use plastics are commodities derived from petrochemicals that are intended to be used just once before being thrown away. Most commonly used in the packaging industry, single-use plastics remain in the environment for a long time, and longer while composting.

But what exactly makes single-use plastic a threat to our ecosystem? Here’s what-

1. Marine Litter:

Mismanagement of plastic waste which accounts for around 15 million tonnes, ends up in the Indian ocean. This strangles marine life and in severity causes fatal organ failures for the fisheries. After prolonged degradation of the sea bed, this plastic degrades to microplastic that’s nearly impossible to detect.

2. Waste Emissions:

For responsible disposal, the plastic that gets incinerated produces toxic fumes that exacerbate the environment. Moreover, these fumes are responsible for n diseases including skin cancer. Thereby, requiring a specialized compost facility with rigorous and environment-friendly processing.

3. Microplastic Fragmentation:

You must have heard the negative impact of snipping off the corner of a package. If not, the smaller fragments are the hardest to decompose. They end up in the crevices of the recycling machinery and remain long lost.

From as small as a candy wrapper to a PVC banner, single-use plastic has been dominating the industry. The preceding effects are just a bitty scenario, but the trajectory has a lot to address. Hence, the need to crack down on the SUPs becomes significant.

Under sections 3, 6, and 25 of the Environment Protection Act, the center notified a three-stage ban on single-use plastics, thereby ensuring the commoditization of reusable and compostable materials. Likewise, many government initiatives are underway for the environmentally sound.

Radical Approach to Plastic Waste Recycling with Chemipearl

With a three-stage ban on the manufacturing, distribution, sale, and import of SUPs, it is high time to build a holistic alternative market. However, one of the major concerns accounting for green alternatives is cost-cut availability.

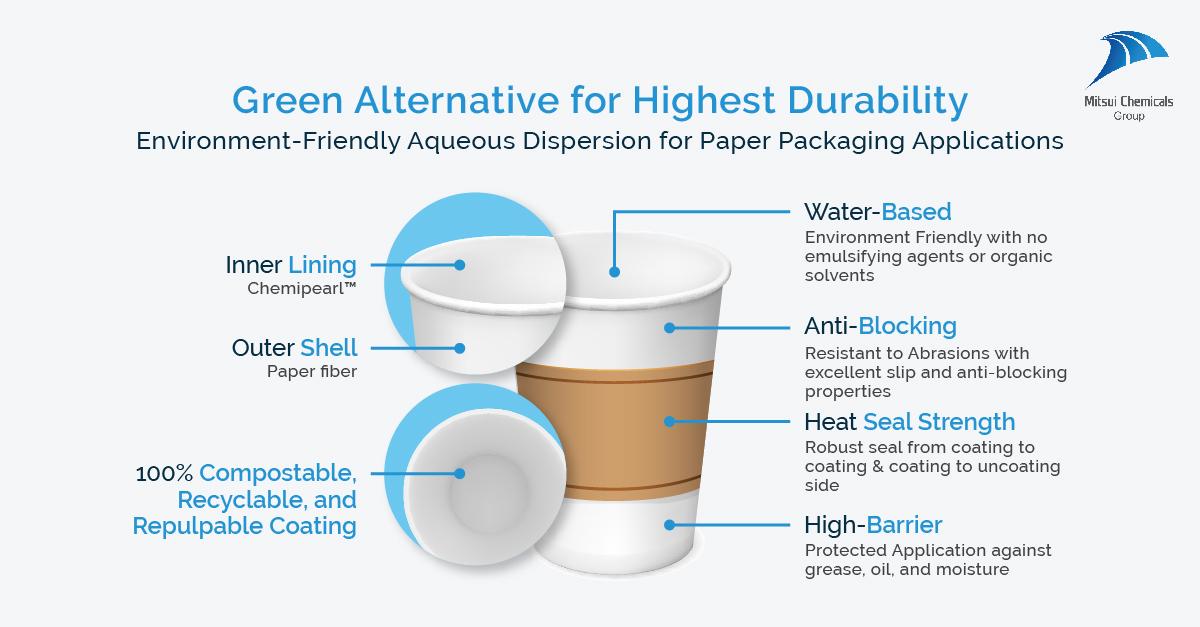

Mitsui Chemicals India leverages unique technology to bolster the single-use plastic ban for the Indian market. The debate on plastic versus recyclable materials has now been monetized by the government, and we are ready to fill the gap. Combatting the issue of PE coating over materials, Chemipearl holds an exceptional strength to meet the power waste management rule of recyclability and composability.

To realize the best of our vision, we stand out in our manufacturing capabilities locally. Recognizing the growing competitiveness in the Indian market, we back it up with Japanese Patented Technology. This way, Chemipearl™ coating offers a recyclable & repulpable alternative for any polyethylene-coated paper packaging material.

When combined with Chemipearl, the packaging can be easily processed through the paper recycling stream using conventional paper recycling equipment. This provides great potential for post-consumer reliability. Unlike traditional plastic coatings which break into large, light flakes that clog the screens during the recycling process, Chemipearl™, fragments into small dense particles that are easily removed as part of the recycling process.

Some of the major properties of Chemipearl that make it the next best alternative include-

1. High Barrier:

Chemipearl is an aqueous dispersion that exhibits water & oil resistance along with excellent heat seal properties making it distinctly fit for the packaging industry.

Besides the eco-friendly coating, the water & oil resistant property with US/FDA 175.105 & 175.300 compliance of direct food contact, CHEMIPEARL makes it ideal for widespread use in PAPER food packaging.

2. Better Adhesiveness:

Beyond easy application, it has superior slip properties that produce a clear, smooth coating for a wide range of demanding paper-packaging applications including dry food, dairy, bakery, powder, meat, ice cream, and frozen food.

3. Heat Seal Strength:

Taking Japanese technology into handy, Chemipearl offers flexible yet robust seal strength from coating to coating & coating to the uncoating side at low temperature. This, in turn, offers an alternate substitute to PE-laminated/coated in paper and paperboard packaging applications.

4. Environment-Friendly:

Serving the righteous purpose to combat plastic waste in India, alternatives such that of Chemipearl have proven wildly effective and direct substitutes to PE laminated/Coated Paper & paperboard.

Only collective efforts would ease the staggering reliability of the packaging industry on plastic. If you choose sustainability as your only choice and wish to seek reliable alternatives to help you fulfill this mission, contact us.