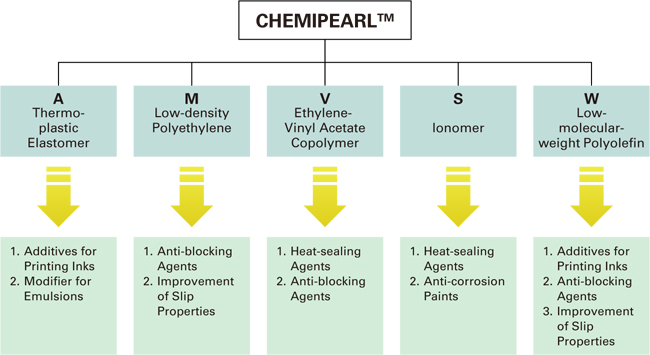

Additives for printing ink and heat sealants

CHEMIPEARL™

Polyolefin-based Aqueous Dispersion

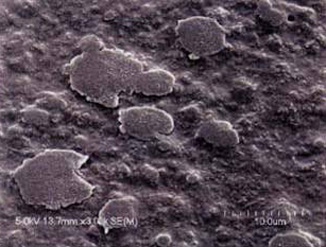

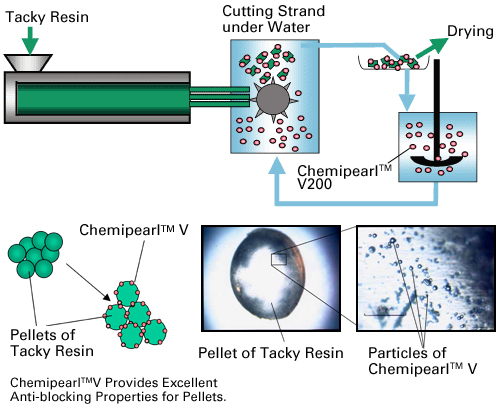

CHEMIPEARL™ is made of fine particles of polyolefin. It uses Mitsui Chemicals’ unique technology and is an environment-friendly water based coating which does not use emulsifying agents or organic solvents (except for some grades and products being in development).

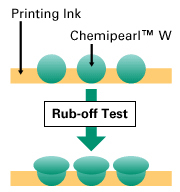

It is abrasion resistant, has improved slip properties, is an anti-blocking agent, has superior application properties as well as outstanding heat-sealing properties and hygienic qualities.

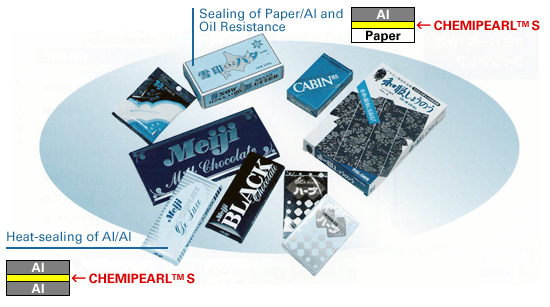

Applications detail

Applications

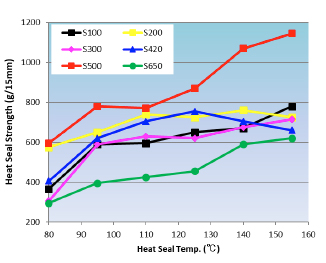

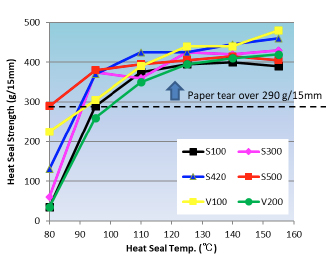

Characteristics

- Basic information

- Details of Characteristics

- Details of Applications

BASIC INFORMATION

CHEMIPEARL™ is a particulate aqueous dispersion developed by Mitsui Chemicals Inc. It is an unique product made of fine particles of polyolefins, previously considered extremely difficult to disperse in water. When compared with widely used aqueous dispersion techniques CHEMIPEARL™ is unique in that it does not use emulsifying agents or organic solvents making it highly environment-friendly. Characteristics of polyolefins, such as mechanical, water and chemical resistant properties are retained intact and make the product ideal for widespread use as printing ink additives, heat sealing for food packaging, adhesives and binders and anti-blocking agents.